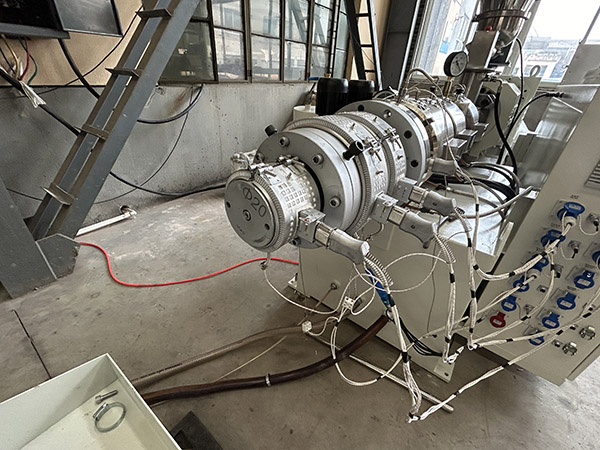

Saboda halaye na cpvc albarkatun kasa, dunƙule, ganga, mutu mold, ja-off da abun yanka zane bambanta da upvc bututu extrusion line.

Yau bari mu mayar da hankali a kan dunƙule da kuma mutu mold zane.

Yadda za a canza ƙirar dunƙule don extrusion bututu cpvc

Gyara ƙirar dunƙule don fitar da bututun CPVC ya haɗa da gyare-gyare don haɓaka narkewa, haɗawa, da isar da kayan CPVC. Anan akwai wasu la'akari don gyara ƙirar dunƙule:

1. **Screw Geometry**:

- Gyara zurfin jirgin da farar jirgi: Daidaita zurfin jirgin da farar jirgi na iya haɓaka isarwa da haɗuwa da kayan CPVC a cikin tashar dunƙulewa.

2. **Rashin Matsi**:

- Haɓaka rabon matsawa: Mafi girman narke danko na CPVC na iya buƙatar ƙimar matsawa mafi girma don samar da isasshen matsi da ƙarfi don narkewa da haɗawa.

3. **Kayan Kaya da Rufi**:

- Yi amfani da kayan aiki ko sutura tare da haɓaka juriya na lalacewa da juriya na lalata don jure yanayin abrasive da lalata yanayin sarrafa CPVC.

- Yi la'akari da sutura ko jiyya waɗanda ke rage gogayya da haɓaka kaddarorin sakin don haɓaka kwararar CPVC da rage lalacewa.

4. **Screw Cooling/Huating**:

- Aiwatar da yankunan dumama/ sanyaya tare da dunƙule ganga don sarrafa narke zafin jiki da danko, musamman a wuraren da CPVC iya fuskanci thermal lalatar ko overheating.

5. **Screw Cooling**:

- Tabbatar da sanyaya mai kyau don kula da yanayin zafin jiki da kuma hana zafi mai zafi na narke CPVC, musamman a cikin matakan extrusion mai sauri.

Ta hanyar la'akari da waɗannan abubuwan da yin gyare-gyare masu dacewa ga ƙirar dunƙule, masana'antun za su iya haɓaka hanyoyin fitar da bututun CPVC don cimma daidaiton narkewar ingancin, kamanni, da fitarwa.

Yadda za a canza ƙirar mutu don extrusion bututu cpvc

Gyara da mutu zane ga CPVC bututu extrusion ya ƙunshi sabawa zuwa saukar da CPVC ta mafi girma narke danko da kuma tabbatar da uniform extrusion.

1. **Mutu Dumu-dumu/Cikin sanyaya**:

- Daidaita wurare masu dumama/ sanyaya: Mafi girman yanayin aiki na CPVC na iya buƙatar gyare-gyare ga tsarin dumama / sanyaya mai mutu don kula da yanayin zafin da ya dace da hana zafi ko sanyaya.

2. **Kayan Kayayyaki da Rubutu**:

Yi la'akari da yin amfani da kayan / sutura tare da mafi girman juriya na zafi: CPVC mafi girman yanayin yanayin aiki na iya buƙatar kayan mutuwa ko sutura waɗanda za su iya jure yanayin zafi ba tare da lalacewa ba.

3. **Mutu Ƙarshen Ƙarshen Sama**:

- Tabbatar da ƙarewar ƙasa mai santsi da uniform: Tsarin mutuwa mai santsi yana taimakawa rage jujjuyawar ƙarfi da ƙarfi, rage haɗarin narkewar karaya da tabbatar da fitar da uniform.

4. **Na'urorin Kula da Yawo ***:

- Haɗa na'urorin sarrafa kwararar ruwa, kamar masu sakawa ko masu ƙuntatawa, don haɓaka rarraba kwararar ruwa da daidaiton matsi a cikin bayanan mutun, musamman a cikin rikitattun geometries mutu.

5. ** Die Design Simulation ***:

- Yi amfani da software na simintin ƙira don tantance halayen kwarara, rarraba matsa lamba, da bayanan martaba a cikin mutu. Wannan yana ba da damar gwajin kama-da-wane na gyare-gyaren mutuwa daban-daban don haɓaka aiki kafin aiwatar da jiki.

Ta hanyar la'akari da waɗannan abubuwan da yin gyare-gyare masu dacewa ga ƙirar mutu, masana'antun na iya haɓaka hanyoyin fitar da bututun CPVC don cimma daidaiton inganci da daidaiton girma.

A cikin extrusion tsari na cpvc bututu, abin da maki ya kamata a yi hankali

A lokacin aikin extrusion na CPVC (Chlorinated Polyvinyl Chloride) bututu, maki da yawa suna buƙatar kulawa da hankali don tabbatar da samar da bututu masu inganci. Ga wasu mahimman batutuwa:

1. **Tsarin Kayayyaki da Haɗawa**:

- Tabbatar da kulawa da dacewa da haɗakar da guduro na CPVC da ƙari don cimma daidaituwa iri ɗaya da daidaito a cikin kayan. Haɗin da ya dace yana da mahimmanci don kiyaye abubuwan da ake so na fili na CPVC.

2. **Irin zafin jiki**:

- Saka idanu da sarrafa zafin jiki na extrusion a hankali, kamar yadda kayan CPVC ke da takamaiman buƙatun zafin jiki don aiki. Kula da zafin jiki a cikin kewayon da aka ba da shawarar don hana lalata kayan kuma tabbatar da kwararar narkewa.

3. ** Zane-zane da Kanfigareshan ***:

- Yi amfani da sukurori waɗanda aka tsara musamman don sarrafa kayan CPVC. Tsarin dunƙule ya kamata ya samar da isasshen hadawa da homogenization na narkewa yayin rage girman dumama don guje wa lalata kayan abu.

4. **Die Design and Calibration**:

- Tabbatar cewa ƙirar mutun ta dace da fitar da bututun CPVC, tare da ma'auni masu dacewa da lissafi don samar da bututu tare da daidaiton kauri da diamita. Daidaita mutun da kyau don cimma girman bututu iri ɗaya.

5. **Sannan da Kwance**:

- Aiwatar da ingantattun tsarin sanyaya da kashewa don kwantar da bututun CPVC da aka fitar da sauri da saita girmansa. Kyakkyawan sanyaya yana da mahimmanci don hana yaƙe-yaƙe ko ɓarna bututu da tabbatar da kwanciyar hankali.

6. **Jawo da Girmamawa**:

- Sarrafa saurin ja da girman bututun CPVC don cimma girman da ake so da ƙarewar saman. Jawo mai kyau da girma yana tabbatar da daidaito a diamita na bututu da kaurin bango a tsawon tsawon bututun.

7. ** Kulawa da Kulawa Mai Kyau ***:

- Aiwatar da tsarin kulawa da inganci don gano duk wani lahani ko rashin daidaituwa a cikin bututun CPVC da aka fitar. Gudanar da bincike na yau da kullun da gwaje-gwaje don tabbatar da bin ƙayyadaddun bayanai da ƙa'idodi.

Ta hanyar sarrafa waɗannan maki a hankali yayin aiwatar da extrusion, masana'anta na iya samar da bututun CPVC masu inganci waɗanda suka dace da ƙayyadaddun ƙayyadaddun da ake buƙata da ƙa'idodin aiki.

Lokacin aikawa: Afrilu-02-2024