01 Ka'idodin injina

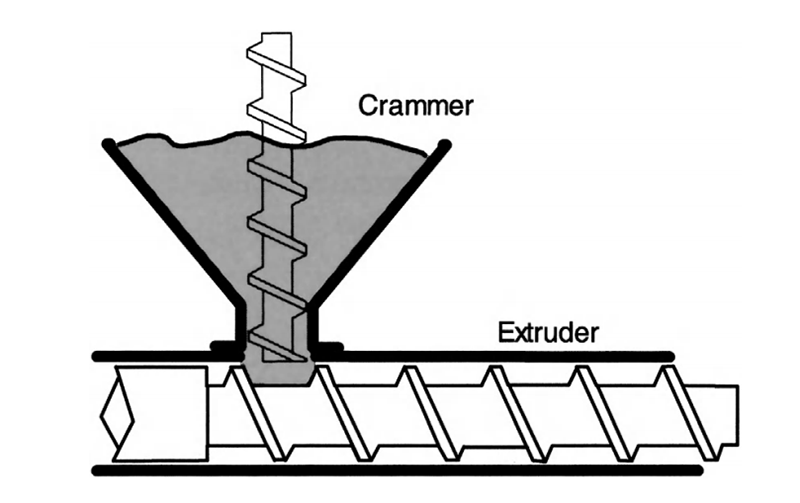

Asalin tsarin extrusion yana da sauƙi – dunƙule yana juyawa a cikin silinda kuma yana tura filastik gaba.Screw a haƙiƙa wani bevel ne ko ramp wanda aka raunata a kewayen tsakiyar Layer.Manufar ita ce ƙara matsa lamba don shawo kan juriya mafi girma.A cikin yanayin extruder, akwai nau'ikan juriya guda 3 don cin nasara: juzu'i na ƙaƙƙarfan barbashi (feed) akan bangon silinda da juzu'in juna a tsakanin su lokacin da dunƙule ya juya kaɗan (yankin ciyarwa);adhesion na narkewa zuwa bangon Silinda;Juriya na narkewar kayan aiki na ciki lokacin da aka tura shi gaba.

Yawancin dunƙule guda ɗaya zaren hannun dama ne, kamar waɗanda ake amfani da su wajen aikin itace da injuna.Idan aka duba su daga baya, suna juya akasin haka saboda suna yin iya ƙoƙarinsu don juyar da ganga baya.A cikin wasu tagwayen dunƙule extruders, screws biyu suna jujjuya gaba ɗaya a cikin silinda guda biyu kuma su ketare juna, don haka dole ne ɗayan ya kasance yana fuskantar dama ɗayan kuma ya kasance yana fuskantar hagu.A cikin sauran tagwayen sukulan cizo, sukulan biyu suna juyawa a hanya ɗaya don haka dole ne su kasance da daidaitawa iri ɗaya.Duk da haka, a kowane hali, akwai ƙwaƙƙwaran ƙwanƙwasa waɗanda ke ɗaukar ƙarfin baya, kuma ƙa'idar Newton har yanzu tana aiki.

02 thermal ka'ida

Fitattun robobi sune thermoplastics-suna narke lokacin da zafi kuma suna sake ƙarfafawa lokacin sanyaya.Daga ina zafin robobin narkewa ke fitowa?Ciyarwar preheating da Silinda / Mutuwar dumama na iya aiki kuma suna da mahimmanci a farawa, amma ƙarfin shigar da motar - zafin da ake samu a cikin silinda lokacin da motar ta juya dunƙule a kan juriya na narkewa mai ɗanɗano - shine mafi mahimmancin tushen zafi. don duk robobi, ban da ƙananan tsarin, ƙananan sauri sukurori, babban narke zafin jiki robobi, da kuma extrusion shafi aikace-aikace.

Ga duk sauran ayyuka, yana da mahimmanci a gane cewa injin harsashi ba shine tushen zafi na farko a cikin aiki ba don haka yana da ƙarancin tasiri akan extrusion fiye da yadda muke tsammani.Zazzabi na baya na iya zama mahimmanci saboda yana shafar ƙimar da ake jigilar daskararru a cikin meshing ko ciyarwa.Ya kamata yanayin zafi ya mutu da gyaɗa ya zama zafin narke da ake so ko kusa da shi, sai dai idan an yi amfani da su don takamaiman manufa kamar fenti, rarraba ruwa, ko sarrafa matsa lamba.

03 Ka'idar raguwa

A mafi yawan extruders, ana samun canjin saurin dunƙule ta hanyar daidaita saurin motar.Motar yawanci tana jujjuyawa da cikakken gudun kusan 1750rpm, amma hakan yana da sauri da sauri don dunƙule fiɗa ɗaya.Idan an jujjuya shi a irin wannan saurin sauri, ana haifar da zafi mai yawa, kuma lokacin zama na filastik ya yi gajere don shirya uniform, narke mai kyau.Matsakaicin raguwa na yau da kullun tsakanin 10:1 da 20:1.Mataki na farko yana iya zama ko dai mai kayan aiki ko kuma jan hankali, amma mataki na biyu yana da kyau kuma an sanya dunƙule a tsakiyar babban kayan aiki na ƙarshe.

A wasu na'urori masu motsi a hankali (kamar tagwayen sukurori don UPVC), za'a iya samun matakan raguwa 3 kuma matsakaicin gudun yana iya zama ƙasa da 30 rpm ko ƙasa da haka (rabo har zuwa 60: 1).A wani matsananci, wasu dogayen tagwayen sukurori don motsawa na iya yin gudu a 600rpm ko sauri, don haka ana buƙatar ƙarancin ragewa sosai tare da sanyaya mai zurfi.

Wani lokaci ƙimar ragewa ba ta dace da aikin ba – kuzari da yawa ba a amfani da shi – kuma yana yiwuwa a ƙara saitin juzu'i tsakanin injin da matakin raguwa na farko wanda ke canza matsakaicin gudu.Wannan ko dai yana ƙara saurin juzu'i fiye da iyakacin da ya gabata ko kuma ya rage matsakaicin gudu, ƙyale tsarin yayi aiki a mafi girman kaso na matsakaicin saurin.Wannan yana ƙara ƙarfin da ake samu, yana rage amperage kuma yana guje wa matsalolin mota.A cikin lokuta biyu, fitarwa na iya ƙaruwa dangane da kayan da buƙatun sanyaya.

Latsa lamba:

Qing Hu

Langbo Machinery Co., Ltd

No.99 Lefeng Road

215624 Garin Leyu Zhangjiagang Jiangsu

Lambar waya: +86 58578311

EMail: info@langbochina.com

Yanar Gizo: www.langbochina.com

Lokacin aikawa: Janairu-17-2023